Advancements in Concrete Core Drilling Machines

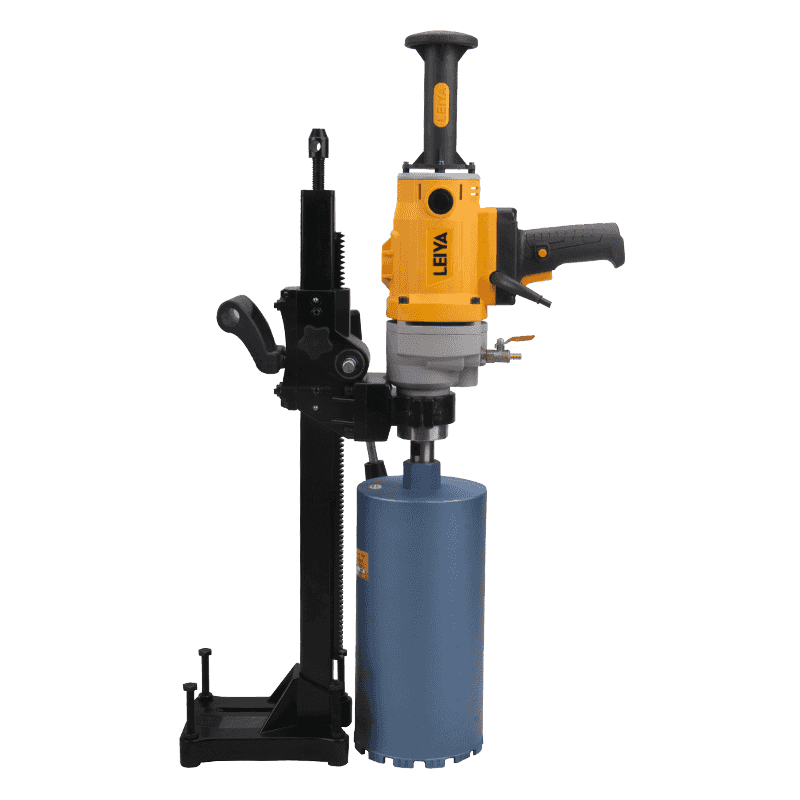

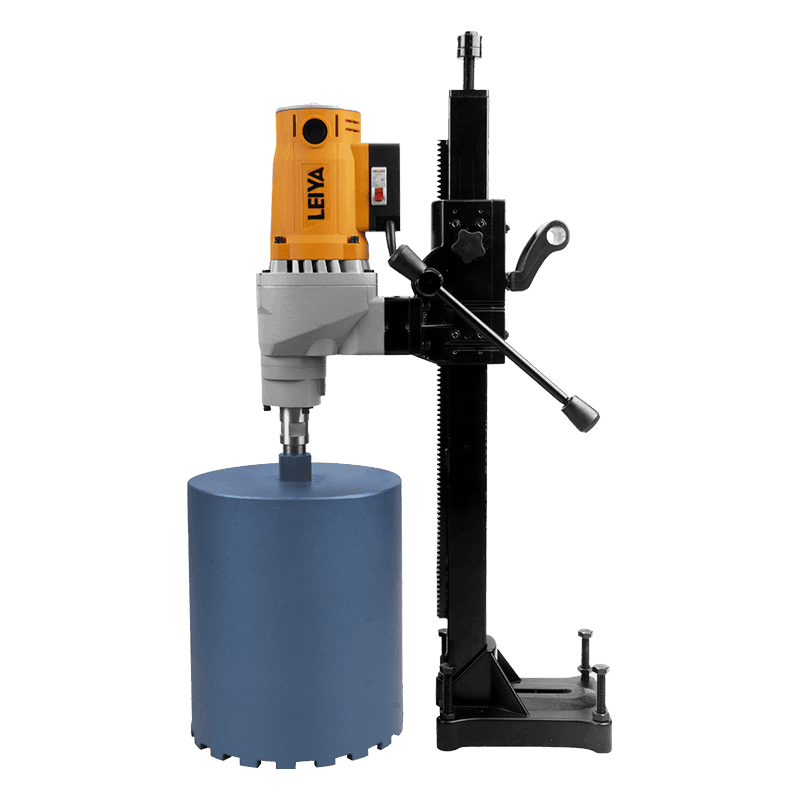

Concrete core drilling machines have become indispensable tools in the construction and engineering industries, playing a crucial role in various applications such as creating openings for plumbing, and electrical installations, and sampling concrete structures.

One of the key innovations in concrete core drilling machines is the integration of diamond drilling technology. Traditional core drilling methods often used carbide or high-speed steel drill bits, which were effective but had limitations in terms of speed and durability. Diamond drilling, on the other hand, utilizes industrial-grade diamond-tipped drill bits, offering superior hardness and wear resistance. This results in faster drilling speeds, increased precision, and extended tool life, ultimately reducing project timelines and costs.

Another significant improvement lies in the automation features of modern concrete core drilling machines. Advanced control systems, such as computer numerical control (CNC), enable operators to program drilling patterns with high precision. This not only enhances accuracy but also reduces the risk of human error, ensuring consistent and reliable results. Automation features also contribute to increased safety on construction sites, as operators can control the machine from a distance, minimizing exposure to potential hazards.

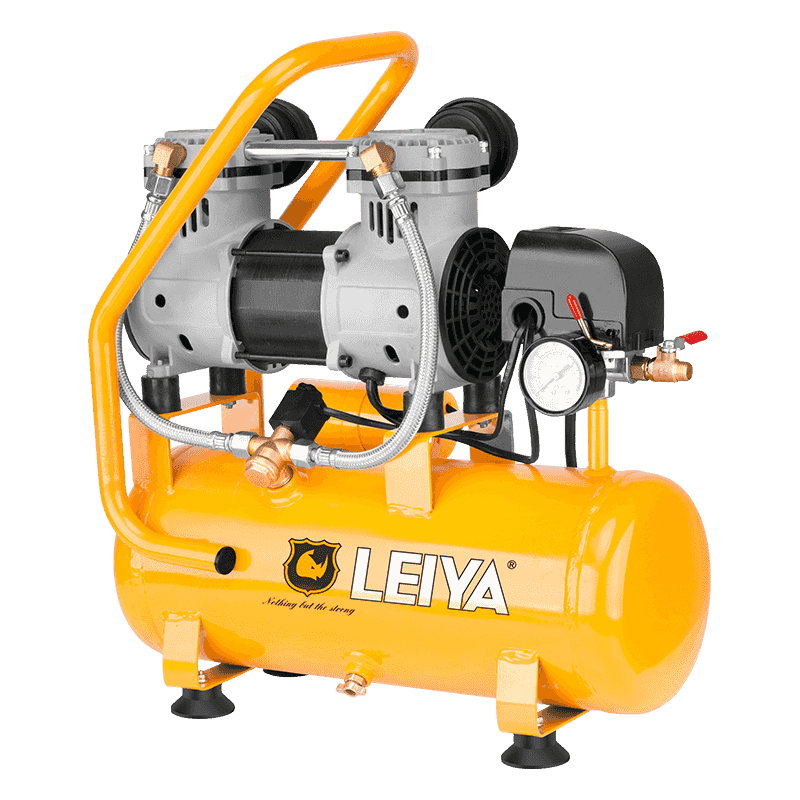

Portability and maneuverability have also been addressed in recent designs of concrete core drilling machines. Compact and lightweight models equipped with ergonomic handles and wheels make it easier for operators to transport and position the machine in confined spaces. This flexibility is especially valuable in urban construction environments where limited space is a common challenge.

Environmental considerations have also driven innovation in concrete core drilling machines. Manufacturers are increasingly incorporating energy-efficient components and designing machines with reduced noise and vibration levels. This not only improves the working conditions for operators but also aligns with sustainability goals in the construction industry.

Evolution of Diamond Grinder Bit Machines in Material Processing

Diamond grinder bit machines have revolutionized material processing industries by providing a cutting-edge solution for precision grinding. These machines, equipped with industrial-grade diamond bits, play a pivotal role in tasks ranging from surface preparation to intricate shaping in various applications such as construction, manufacturing, and metalworking.

The key advantage of diamond grinder bit machines lies in the use of diamond as an abrasive material. Diamonds are renowned for their exceptional hardness, making them highly effective in grinding through tough materials like concrete, metal, and stone. Unlike traditional grinder bits that wear out quickly, diamond bits maintain their sharpness for an extended period, resulting in increased efficiency and cost-effectiveness.

One notable evolution in diamond grinder bit machines is the integration of advanced control systems. Modern machines often feature adjustable speed settings and automated controls, allowing operators to tailor the grinding process to specific materials and project requirements. This level of customization enhances precision and efficiency, contributing to higher-quality finished products.

The versatility of diamond grinder bit machines is another key aspect of their evolution. Manufacturers have developed a range of diamond bits for different applications, including coarse grinding, fine polishing, and specialized tasks like beveling or chamfering. This adaptability makes these machines suitable for a wide array of industries, from construction and metal fabrication to semiconductor manufacturing.

Environmental considerations have also influenced the design of diamond grinder bit machines. Manufacturers are increasingly incorporating features to minimize dust emissions, such as integrated dust extraction systems. This not only improves air quality in the workplace but also aligns with industry standards and regulations.

English

English Deutsch

Deutsch русский

русский عربى

عربى Español

Español

+86(579) 8796 5708

+86(579) 8796 5708