The Reliability of the Corded Angle Grinder

The corded angle grinder, a stalwart in the arsenal of power tools, has consistently proven itself as an essential companion for professionals and DIY enthusiasts. Unlike its cordless counterparts, the corded angle grinder relies on a direct power source, providing uninterrupted energy for a variety of cutting, grinding, and polishing applications.

One of the primary advantages of the corded angle grinder lies in its continuous power supply. Connected directly to an electrical outlet, this tool eliminates concerns about battery life and ensures consistent performance throughout the task at hand. This uninterrupted power is particularly advantageous for extended applications, where sustained force is essential for optimal results.

The robust performance of corded angle grinders makes them well-suited for heavy-duty tasks. Whether it's cutting through tough materials like metal or concrete or grinding and polishing surfaces, these tools deliver high-speed rotations and ample torque. The corded design allows for increased power output compared to many cordless alternatives, making the corded angle grinder a preferred choice for demanding applications.

Additionally, corded angle grinders often boast durable designs that can withstand the rigors of professional use. These tools are built to handle challenging work environments and frequent use, contributing to their reputation for reliability and longevity.

The corded angle grinder remains a reliable workhorse in the world of power tools. Its continuous power supply, robust performance, and durability make it an indispensable tool for tasks that demand consistent force and precision. As technology advances, we may witness further enhancements in corded angle grinder design, ensuring their continued prominence in workshops, construction sites, and DIY projects.

The Mighty Angle Grinder Machine Versatility in Motion

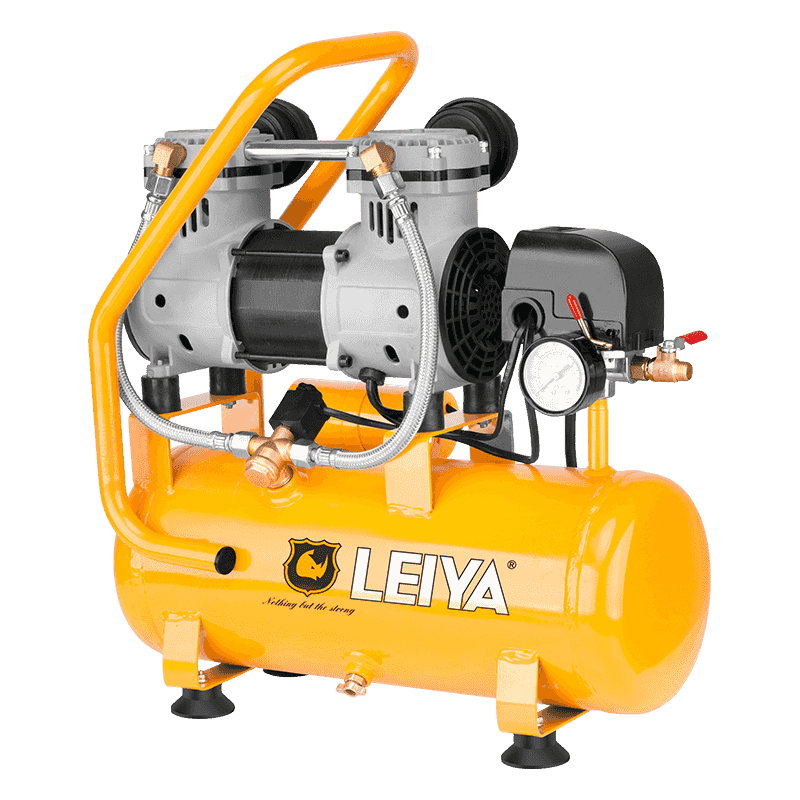

The angle grinder machine stands as a powerhouse in the realm of power tools, revered for its versatility and efficiency across various industries. This compact and robust tool, equipped with a rapidly spinning abrasive disc, has become an indispensable asset in metalworking, construction, and fabrication.

The primary strength of the angle grinder lies in its ability to perform a myriad of tasks with precision and speed. From cutting and grinding to polishing and sharpening, this machine excels in shaping and finishing a wide array of materials, including metal, stone, and concrete. Its adaptability makes it a must-have for professionals and DIY enthusiasts alike.

One of the standout features of the angle grinder is its compact design, allowing users to navigate through tight spaces and tackle intricate tasks. The tool's size belies its power, as it delivers high-speed rotations, generating ample force to handle demanding applications. The ergonomic design of modern angle grinders further enhances user comfort during extended use.

Versatility extends to the range of accessories and attachments available for the angle grinder machine. Different abrasive discs, cutting wheels, and wire brushes can be easily attached, enabling the tool to adapt to specific materials and tasks. This flexibility makes the angle grinder a go-to choice for tasks ranging from heavy-duty metal cutting to delicate surface finishing.

Safety features play a crucial role in the design of angle grinders. Many models are equipped with features like adjustable guards, anti-kickback mechanisms, and ergonomic handles to enhance user safety during operation. Additionally, advancements in motor technology contribute to reduced vibrations and noise levels, further improving the overall user experience.

The angle grinder machine has earned its reputation as a versatile workhorse in the world of power tools. Its compact design, adaptability, and powerful performance make it an indispensable tool for a wide range of applications. As technology continues to advance, we can expect further innovations in angle grinder design, ensuring these machines remain at the forefront of shaping and finishing tasks across various industries.

English

English Deutsch

Deutsch русский

русский عربى

عربى Español

Español

+86(579) 8796 5708

+86(579) 8796 5708