The Aluminum Body Chop Saw Redefining Cutoff Efficiency

The cutoff machine, a quintessential tool in metalworking and construction, leaps forward with the advent of the Aluminum Body Chop Saw. Renowned for its durability, efficiency, and precision, this specialized tool has become an indispensable asset in various industrial applications.

At the core of the Aluminum Body Chop Saw is its robust construction. Crafted with an aluminum body, this saw not only ensures durability but also contributes to its lightweight design, facilitating ease of use and portability. The aluminum construction also plays a crucial role in dissipating heat efficiently during prolonged use, enhancing the tool's overall performance and longevity.

The precision and efficiency of the Aluminum Body Chop Saw lie in its ability to make clean and accurate cuts through various materials, including metals like aluminum, steel, and other alloys. Fitted with high-quality abrasive or carbide-tipped blades, this chop saw excels in creating precise angles and cuts, making it an ideal choice for tasks ranging from metal fabrication to construction projects.

Versatility is a key feature of the Aluminum Body Chop Saw. Its adjustable cutting depth and miter capabilities allow for customization, accommodating a diverse range of cutting requirements. Whether it's a simple crosscut or intricate mitered angles, this chop saw delivers consistent results with ease.

Safety is paramount, and the Aluminum Body Chop Saw incorporates features such as blade guards and safety switches to ensure the protection of the user. Additionally, its ergonomic design minimizes vibrations, reducing operator fatigue during extended use.

The Aluminum Body Chop Saw represents a pinnacle in cutoff machine technology, offering durability, precision, and versatility in a single package.

The Copper Motor Chop Saw Revolutionizing Cut Off Machines

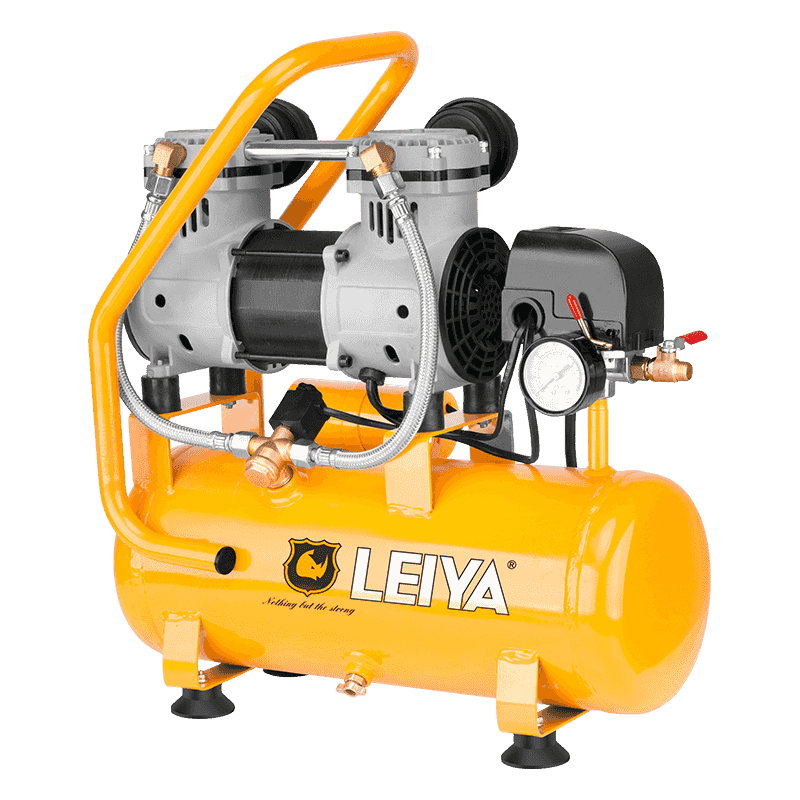

In the realm of cut-off machines, the Copper Motor Chop Saw emerges as a technological marvel, combining the efficiency of a cut-off machine with the power and durability of a copper motor. This specialized tool has redefined the landscape of metalworking and construction, offering precision and reliability in a single, robust package.

The Copper Motor Chop Saw distinguishes itself with its copper motor, a standout feature that contributes to its exceptional performance. Copper motors are known for their high conductivity and efficiency, ensuring consistent power delivery to the saw blade. This not only enhances cutting performance but also extends the tool's lifespan, making it a reliable choice for professionals engaged in metal fabrication, construction, and other heavy-duty applications.

At the heart of the Copper Motor Chop Saw's functionality is its ability to make clean and precise cuts through a variety of materials, including metals like steel, aluminum, and copper. Fitted with specialized abrasive or carbide-tipped blades, this chop saw excels in providing accurate cuts and efficient material removal, catering to diverse cutting needs in industrial settings.

The integration of a copper motor elevates the tool's durability and resilience. Copper is known for its excellent heat dissipation properties, reducing the risk of overheating during prolonged use. This ensures that the Copper Motor Chop Saw maintains optimal performance even in demanding applications, making it an essential tool for professionals seeking efficiency and longevity.

Versatility is another key feature of the Copper Motor Chop Saw. With adjustable cutting depths, miter capabilities, and various blade options, this tool accommodates a wide range of cutting requirements. Its adaptability makes it suitable for tasks ranging from basic crosscuts to intricate mitered angles in metalwork and construction projects.

The Copper Motor Chop Saw stands at the forefront of cut-off machine technology, offering a perfect amalgamation of power, precision, and durability.

English

English Deutsch

Deutsch русский

русский عربى

عربى Español

Español

+86(579) 8796 5708

+86(579) 8796 5708