The Evolution of Cordless Angle Grinders

Cordless angle grinders have emerged as powerful and versatile tools, revolutionizing the way professionals and DIY enthusiasts approach metalworking, construction, and various cutting and grinding tasks. These tools, once tethered by cords, now offer a level of freedom and mobility previously unseen in the world of angle grinders.

One of the key advantages of cordless angle grinders is their portability. Free from the constraints of power cords, these tools provide the flexibility to work in confined spaces, on job sites without easy access to power outlets, or in outdoor environments. This enhanced mobility not only improves efficiency but also promotes safer working conditions by eliminating the risk of tripping over cords.

The heart of cordless angle grinders lies in their battery technology. Lithium-ion batteries, with their high energy density and quick recharge capabilities, have played a pivotal role in the advancement of cordless tools. These batteries provide ample power to drive the grinder's motor, ensuring sustained performance during demanding tasks. The convenience of cordless operation, combined with powerful battery technology, has made these grinders an indispensable choice for professionals in the field.

Adjustable speed settings and ergonomic designs further contribute to the versatility and user-friendliness of cordless angle grinders. Users can tailor the tool's performance to suit the specific material being worked on, whether it's metal, stone, or concrete. Comfortable grips and handles reduce operator fatigue during prolonged use, enhancing the overall user experience.

As technology continues to progress, manufacturers are focusing on optimizing brushless motor technology in cordless angle grinders. These motors are more energy-efficient, generate less heat, and have a longer lifespan than traditional brushed motors, resulting in tools that are not only powerful but also durable.

The convergence of lithium-ion battery technology, adjustable features, and ergonomic design has elevated these tools to a new level, making them indispensable for professionals and DIY enthusiasts seeking efficiency and flexibility in their metalworking and construction projects.

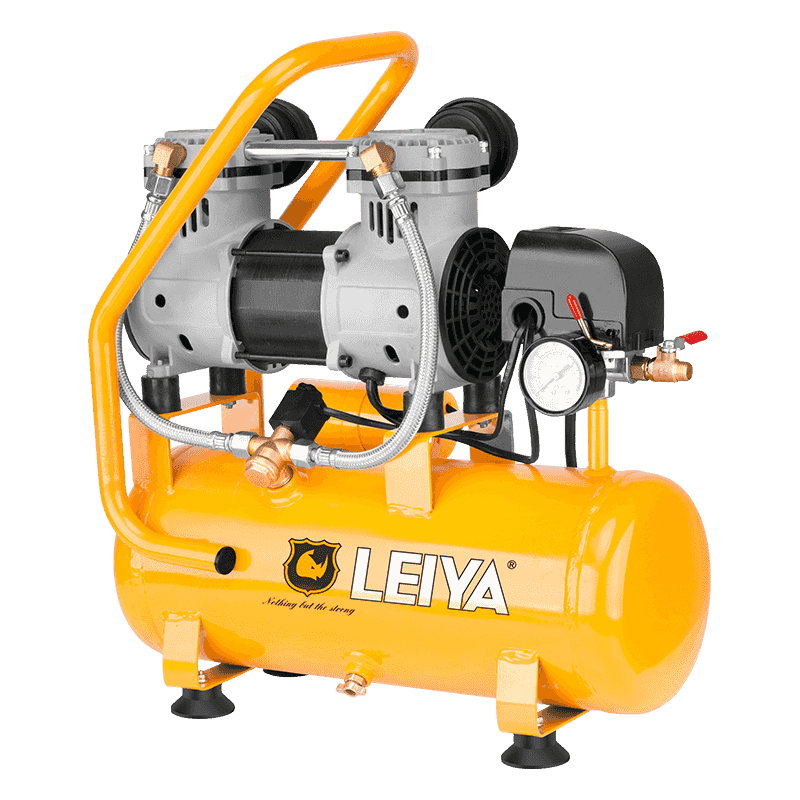

The Pneumatic Die Grinder in Industrial Applications

The pneumatic die grinder, a versatile and powerful tool, has become an indispensable asset in various industrial settings where precision and efficiency are paramount. Operating on compressed air, this tool offers a range of applications from metalworking to deburring, making it a staple in workshops and manufacturing facilities worldwide.

One of the key advantages of pneumatic die grinders lies in their power-to-weight ratio. These compact tools deliver high-speed rotation and torque, enabling them to tackle intricate tasks with unparalleled precision. The lightweight design allows for better maneuverability, making them ideal for intricate detailing and intricate shaping of materials.

The efficiency of pneumatic die grinders is further accentuated by their consistent power output. Unlike electric tools that may experience power fluctuations, pneumatic die grinders maintain a steady level of force, resulting in uniform performance. This reliability is crucial for tasks such as grinding, polishing, and shaping that demand a consistent application of force.

The versatility of pneumatic die grinders is evident in their ability to accommodate various attachments and accessories. Different grinding bits, burrs, and abrasive wheels can be easily attached, allowing the tool to adapt to different materials and applications. This adaptability makes the pneumatic die grinder a go-to choice for tasks ranging from deburring sharp edges to intricate metal detailing.

Another notable feature is the reduced risk of overheating. Pneumatic die grinders generate less heat during operation compared to their electric counterparts, contributing to extended tool life and minimizing the risk of thermal damage to the workpiece.

The pneumatic die grinder stands as a testament to precision and efficiency in industrial applications. Its compact design, consistent power output, and adaptability make it an essential tool for tasks requiring meticulous attention to detail.

English

English Deutsch

Deutsch русский

русский عربى

عربى Español

Español

+86(579) 8796 5708

+86(579) 8796 5708