The Impact of Direct Driven Portable Compressors

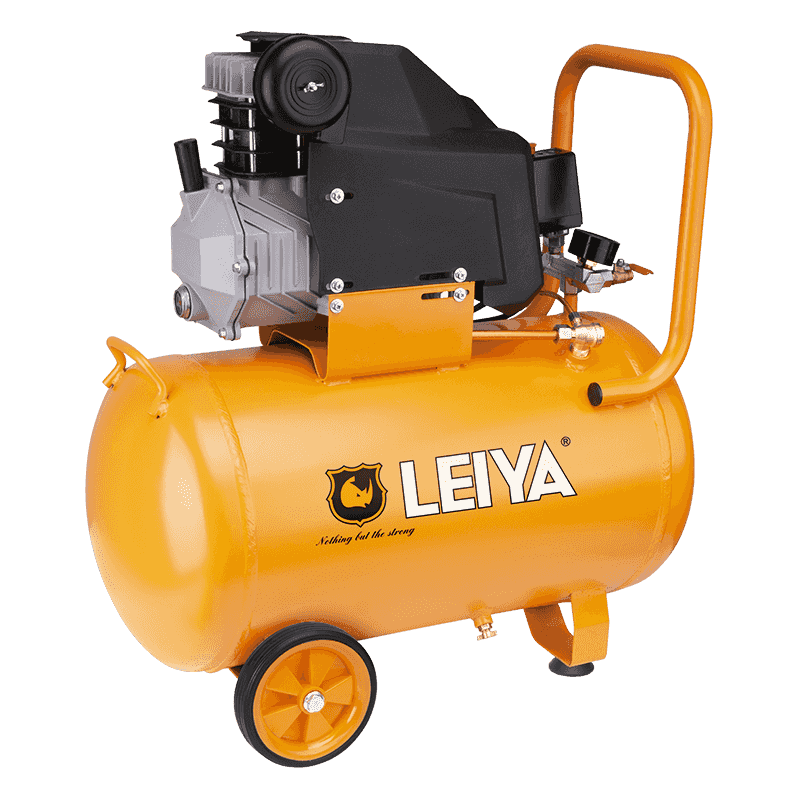

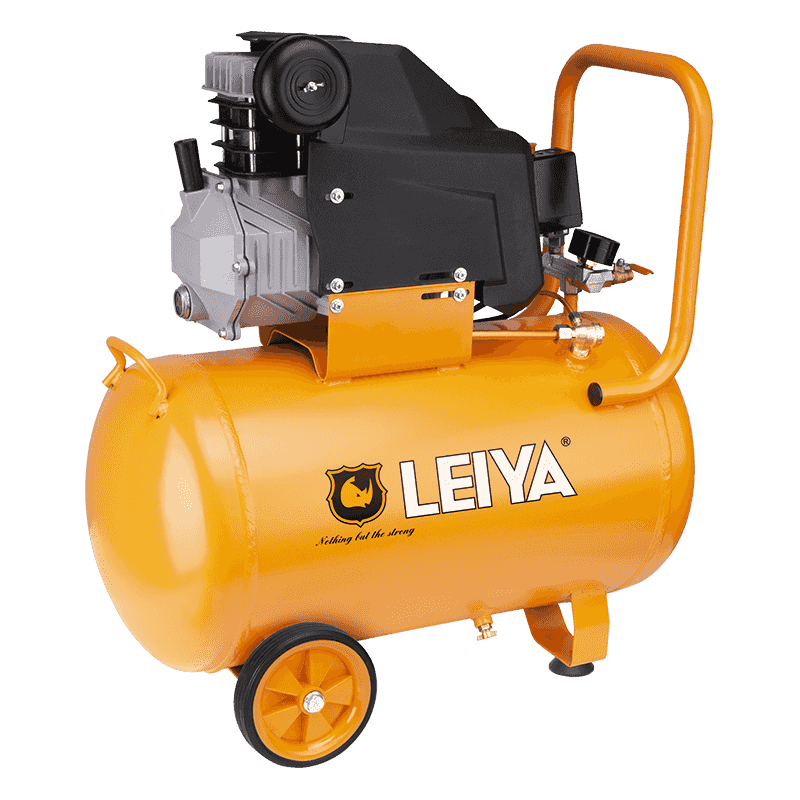

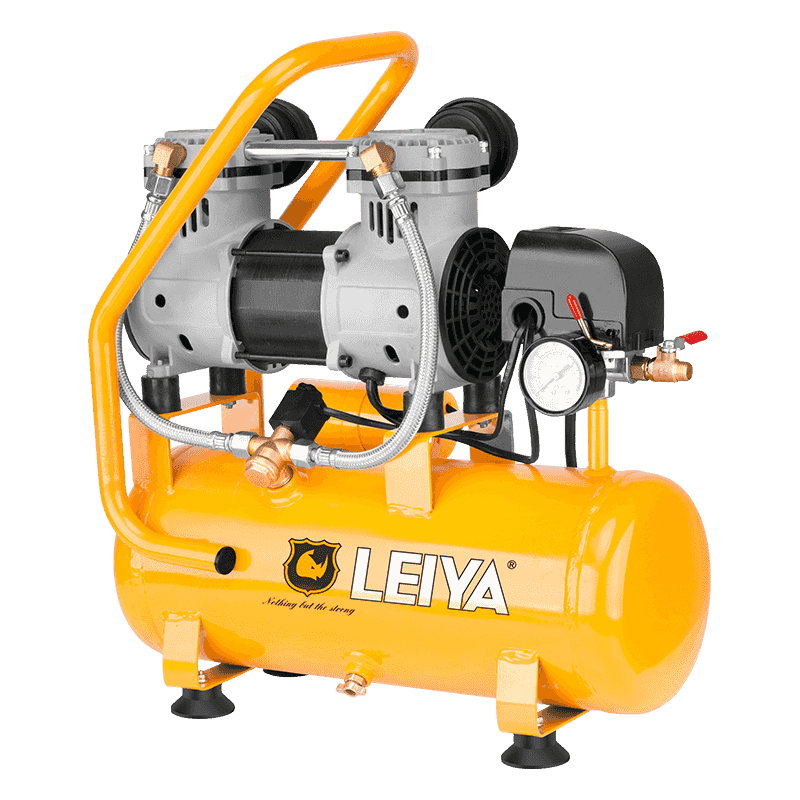

The Direct Driven Portable Compressor is characterized by its compact design and integrated motor and pump. This direct-driven mechanism eliminates the need for additional components, resulting in a streamlined and efficient unit that is easy to transport and operate on various job sites.

One of the primary advantages of this compressor is its portability. The compact and lightweight design, often accompanied by sturdy handles, allows users to move the compressor effortlessly from one location to another. This mobility is especially beneficial in construction sites, workshops, and other settings where compressed air is needed on the go.

The direct-driven configuration of this compressor enhances its overall efficiency. The direct coupling between the motor and the pump reduces energy loss, ensuring a more direct transfer of power and, consequently, optimal performance. This efficiency translates to faster pressurization and reliable delivery of compressed air for a variety of tools and tasks.

Direct Driven Portable Compressors find applications across a spectrum of industries. From powering pneumatic tools like nail guns and impact wrenches to facilitating spray painting and tire inflation, these compressors prove indispensable in diverse work environments. Their adaptability makes them a go-to solution for professionals seeking a reliable and convenient compressed air source.

Many Direct Driven Portable Compressors boast quiet operation, making them suitable for use in noise-sensitive environments. Additionally, their direct-driven design often translates into lower maintenance requirements, contributing to overall cost-effectiveness and ease of ownership.

The Direct Driven Portable Compressor is a game-changer in the world of compressed air applications. Its compact design, efficient performance, and on-the-go versatility make it an indispensable tool for professionals across various industries, ensuring that the power of compressed air is harnessed with maximum efficiency and convenience.

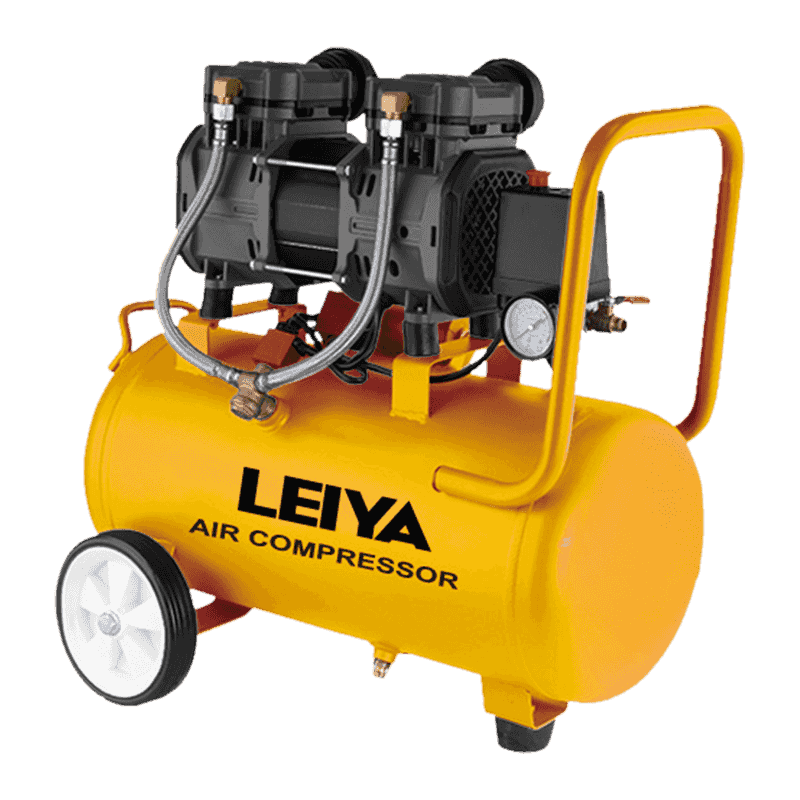

The Advantages of Oil-Free Type Air Compressors

The Oil-Free Type Air Compressor has emerged as a cutting-edge solution in the world of compressed air technology, offering a range of benefits that make it a preferred choice in various industries.

At the heart of the Oil-Free Type Air Compressor is its unique design that operates without the use of oil for lubrication. Traditional compressors often require oil for cooling and lubrication, but the oil-free design minimizes the risk of oil contamination in the compressed air output. This is particularly crucial in applications where oil-free air is essential, such as in pharmaceuticals, food processing, and electronics manufacturing.

By eliminating the presence of oil in the compression process, the Oil-Free Type Air Compressor ensures the delivery of clean, uncontaminated compressed air. This makes it an ideal choice for industries where maintaining air quality standards is critical, preventing any potential harm to sensitive equipment or end-products.

Oil-free compressors typically require less maintenance compared to their oil-lubricated counterparts. The absence of oil means fewer components are susceptible to wear and tear, resulting in reduced maintenance costs and downtime. This feature is especially advantageous for businesses seeking cost-effective and reliable compressed air solutions.

The environmentally conscious design of the Oil-Free Type Air Compressor aligns with sustainability goals. The elimination of lubricating oil reduces the risk of oil disposal and contamination, contributing to a cleaner and greener operation. This aligns with the increasing emphasis on eco-friendly practices in various industries.

These compressors find applications in a wide range of industries, including healthcare, laboratories, and cleanroom environments, where maintaining air purity is paramount. Additionally, the Oil-Free Type Air Compressor is suitable for various pneumatic tools, ensuring a reliable and contaminant-free power source.

English

English Deutsch

Deutsch русский

русский عربى

عربى Español

Español

+86(579) 8796 5708

+86(579) 8796 5708