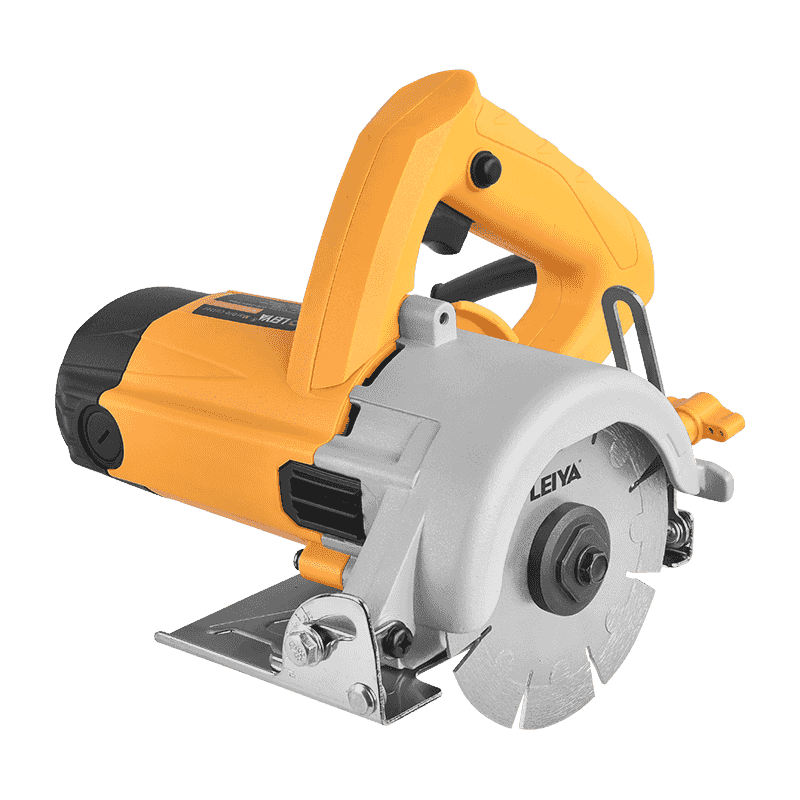

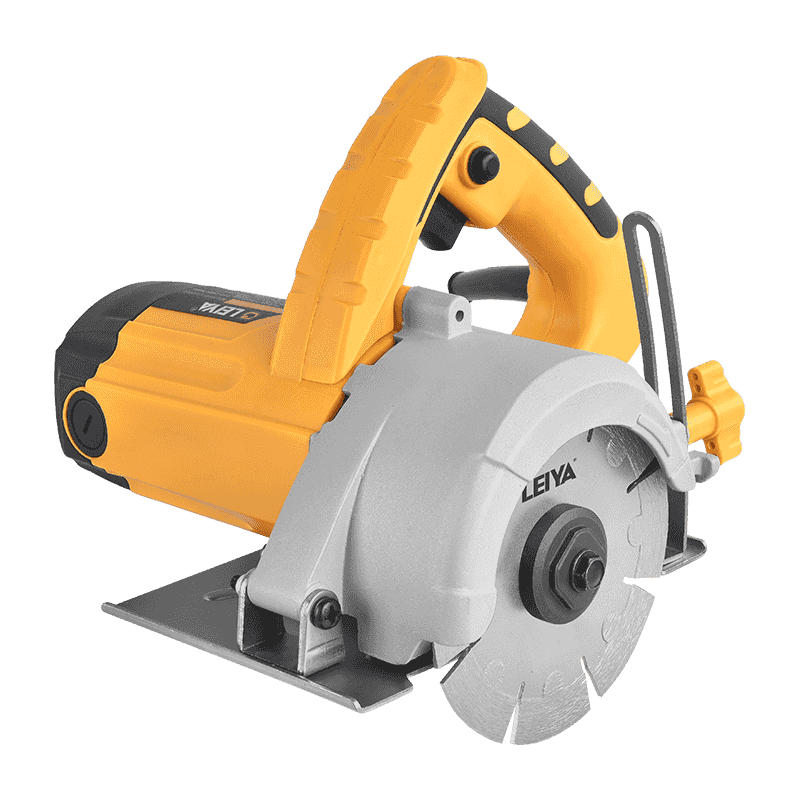

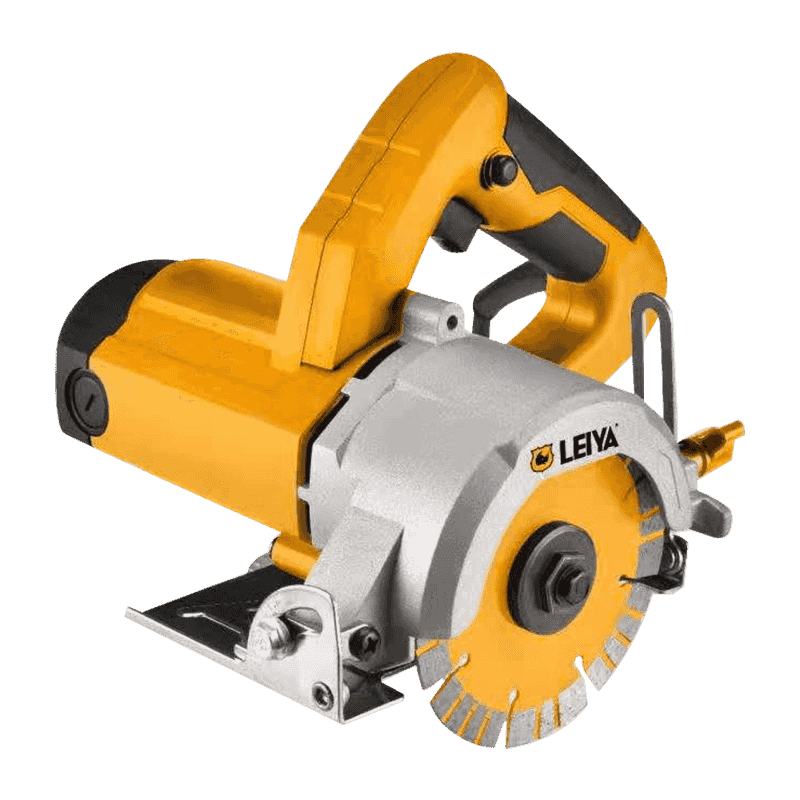

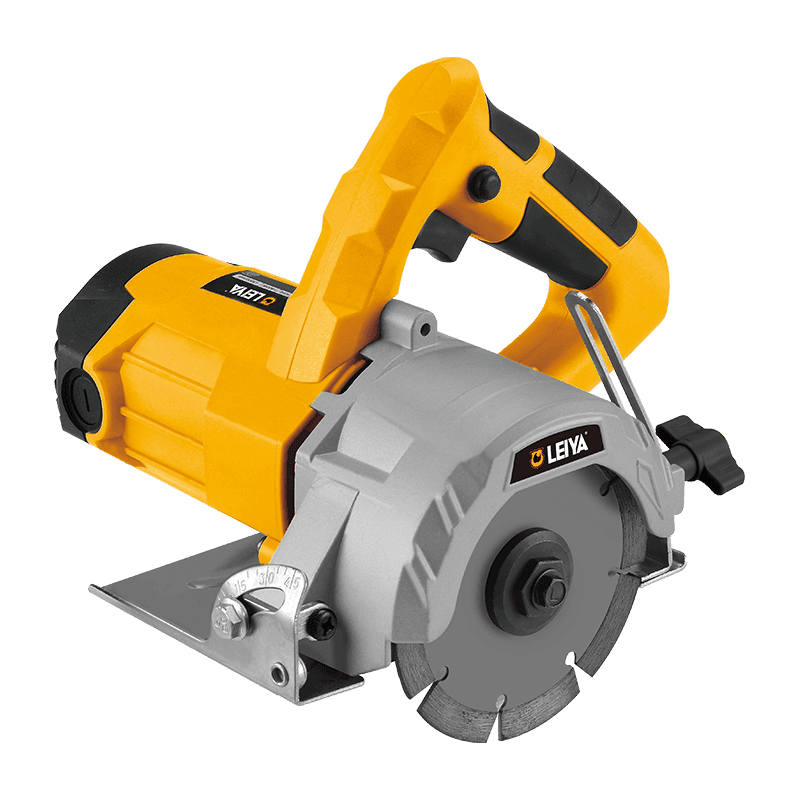

The Cutting Edge Electric Wire Wet Saw Marble Cutter

The electric wire wet saw marble cutter stands out as a cutting-edge tool that has redefined precision and efficiency in the world of stone and tile cutting. This advanced equipment has become a game-changer for professionals in the construction and renovation industries, offering a range of features that elevate the cutting experience.

At the heart of this marble cutter is its electric wire wet saw technology, providing a continuous and smooth cutting motion. Unlike traditional dry saws, the wet cutting method minimizes dust, cools the blade, and enhances the overall cutting precision. This makes it an ideal choice for working with delicate materials like marble, ensuring clean, chip-free cuts and extending the life of the cutting blade.

The versatility of the electric wire wet saw marble cutter extends to its ability to handle various materials with ease. Whether it's marble, granite, porcelain, or other hard surfaces, this tool excels in producing precise cuts for both straight lines and intricate patterns. The precision is further enhanced by features such as adjustable cutting depths and angles, catering to the diverse needs of professionals in the field.

The integration of safety features is a notable aspect of these modern marble cutters. Splash guards and water containment systems reduce the risk of slippage and provide a safer working environment. Additionally, ergonomic designs and anti-vibration technology contribute to user comfort during prolonged use.

Furthermore, electric wire wet saw marble cutters often come with efficient water recirculation systems, optimizing water usage and minimizing waste. This not only adds to the eco-friendliness of the tool but also ensures a cleaner workspace.

The electric wire wet saw marble cutter stands as a testament to the evolution of cutting technology in the construction industry. Its precision, versatility, and safety features make it an indispensable tool for professionals seeking top-tier performance in stone and tile cutting applications.

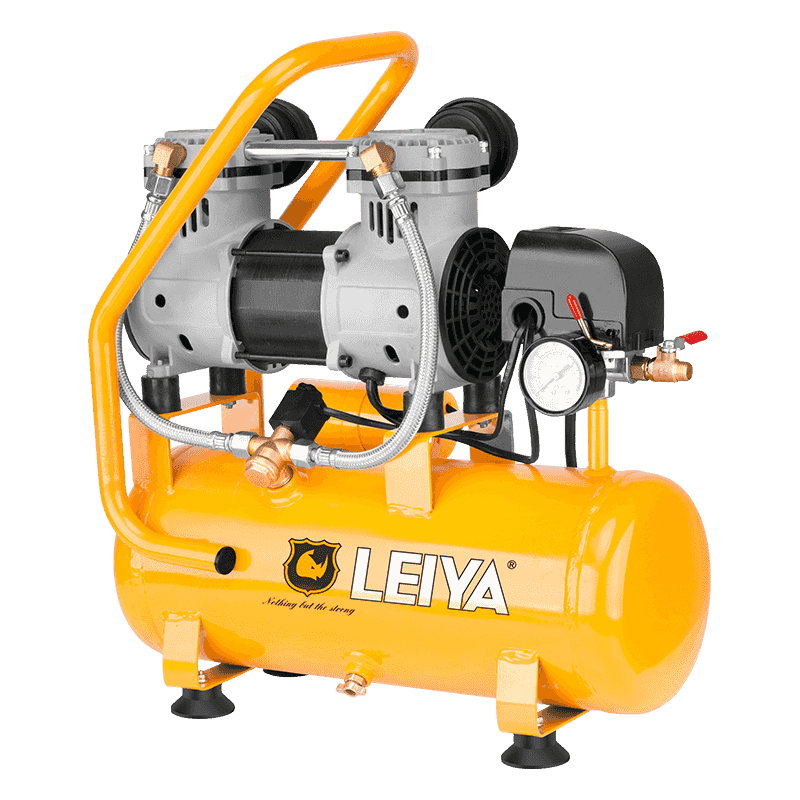

The Cutting Machine Precision and Efficiency in Every Slice

The cutting machine has emerged as a cornerstone in various industries, providing unmatched precision and efficiency in materials processing. This versatile tool has evolved to meet the demands of modern manufacturing, offering a wide array of applications that range from metal fabrication to woodworking.

One of the primary features that make cutting machines indispensable is their ability to deliver precise cuts consistently. Whether it's intricate patterns in textiles, precise shapes in metals, or clean edges in plastics, these machines excel in accuracy. Computer Numerical Control (CNC) technology has further enhanced this precision, allowing for complex designs and intricate cuts with minimal margin for error.

The efficiency of cutting machines is a result of their speed and automation. Unlike manual methods that may be time-consuming and labor-intensive, cutting machines can process materials rapidly and consistently. This not only boosts productivity but also ensures a higher level of uniformity in the finished products.

The adaptability of cutting machines to various materials sets them apart. From metals like steel and aluminum to composites, plastics, and even delicate fabrics, these machines can be equipped with different blades or tools to handle a diverse range of materials. This versatility makes them invaluable in industries such as automotive, aerospace, fashion, and more.

Advancements in cutting machine technology have also focused on user-friendly interfaces and automation features. Touchscreen controls, intuitive software, and programmable settings have made these machines more accessible to operators with varying levels of expertise. Additionally, safety features such as emergency stop mechanisms and sensor-based technologies contribute to a secure working environment. The cutting machine has become a linchpin in manufacturing processes, embodying precision, efficiency, and adaptability.

English

English Deutsch

Deutsch русский

русский عربى

عربى Español

Español

+86(579) 8796 5708

+86(579) 8796 5708