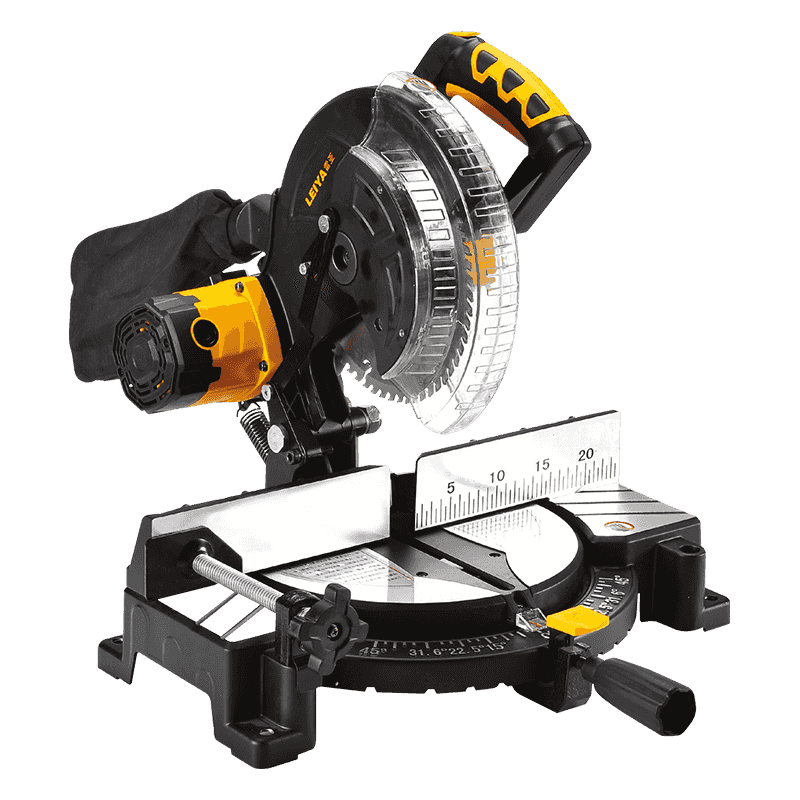

Precision in Motion Sliding Miter Cutting Saw Machine

The sliding miter cutting saw machine has become a hallmark of precision and versatility in the world of woodworking and carpentry. This innovative tool combines the benefits of a miter saw with a sliding mechanism, offering users the ability to make precise angled and beveled cuts while handling wider workpieces.

One of the standout features of the sliding miter cutting saw machine is its ability to move the saw head along a sliding rail. This added mobility allows for increased cutting capacity, enabling users to tackle larger materials with ease. The sliding mechanism is particularly advantageous when working with wide boards or when creating compound miter cuts, enhancing the tool's flexibility for a variety of projects.

The miter aspect of the machine allows for precise angle adjustments, making it ideal for tasks such as crown molding, baseboards, and picture frames. The ability to make accurate miter cuts at various angles enhances the tool's versatility, catering to the intricate demands of both professional carpenters and hobbyists alike.

Additionally, the sliding miter cutting saw machine often incorporates a beveling feature, allowing users to tilt the blade for creating beveled edges or compound miter cuts. This capability adds another dimension to the tool's functionality, making it suitable for a wide range of woodworking applications, including furniture making and custom trim work.

Safety features are a priority in modern sliding miter cutting saw machines. Blade guards, electric brakes, and dust collection systems contribute to a secure and clean working environment. Furthermore, some models include laser guides or LED lights to enhance cutting accuracy, assisting users in aligning their cuts precisely.

The sliding miter cutting saw machine stands as a testament to the evolution of woodworking tools, combining precision, versatility, and safety. Its ability to handle a variety of cuts and accommodate different workpiece sizes makes it an essential tool for professionals and enthusiasts seeking excellence in their woodworking projects.

Advancing Precision and Efficiency Aluminum Sawing Machine

The aluminum sawing machine, a pivotal tool in metalworking and fabrication, has redefined the landscape of cutting technology with its precision, efficiency, and adaptability. This specialized machine caters specifically to the demands of working with aluminum, offering a range of features that make it indispensable in various industries.

At the core of the aluminum sawing machine is its ability to handle aluminum's unique properties. Aluminum is known for its lightweight yet durable nature, making it a popular choice in industries such as aerospace, automotive, and construction. The sawing machine is designed to cut through aluminum with precision, producing clean and accurate cuts in sheets, profiles, and extrusions.

One key feature of the aluminum sawing machine is its adjustable cutting speeds and feed rates, allowing operators to tailor the machine's performance to different aluminum alloys and thicknesses. This adaptability ensures optimal results for various applications, from simple cuts in thin sheets to more intricate and demanding tasks in heavy-duty aluminum profiles.

The efficiency of the aluminum sawing machine is further enhanced by its automated features. Many modern models come equipped with programmable controls, touchscreens, and even CNC technology. These advancements streamline the cutting process, reduce setup times, and enhance overall productivity in industrial settings.

Safety is a paramount consideration in the design of aluminum sawing machines. Blade guards, emergency stop mechanisms, and safety interlocks contribute to a secure working environment.

The aluminum sawing machine evolved to meet the evolving needs of industries that rely on aluminum cutting. Innovations such as laser guides, automatic material clamping, and real-time monitoring systems are pushing the boundaries of what these machines can achieve, solidifying their place as indispensable tools in the world of metal fabrication.

English

English Deutsch

Deutsch русский

русский عربى

عربى Español

Español

+86(579) 8796 5708

+86(579) 8796 5708